06 May 2025

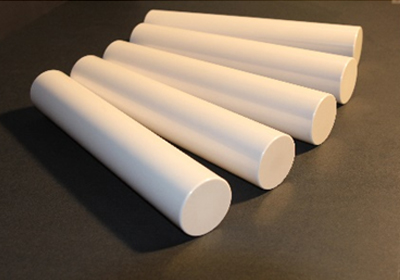

Maintain pharma processing efficiency with homogenizer spare and wear replacement parts from Amon Engineering, designed for durability and precision.

Homogenizer spare and wear replacement parts maintain the efficiency and reliability of pharmaceutical processing equipment. High-performance components ensure uniform particle size reduction, improving product consistency and quality control.

Optimising Pharma Equipment Efficiency with Quality Homogenizer Parts

High-quality spare parts enhance the efficiency of pharmaceutical processing by ensuring stable performance and reducing operational disruptions. Components engineered for superior wear resistance minimise the risk of breakdowns and lower overall maintenance demands.

Material composition directly affects the longevity and functionality of homogenizer parts. Advanced alloys and reinforced polymers withstand repeated mechanical stress, preserving structural integrity and enabling continuous operation without premature failure.

Precision-manufactured components contribute to process consistency and product uniformity. Optimised pressure distribution across homogenizing valves supports even particle size reduction, improving batch reproducibility and meeting stringent pharmaceutical standards.

Routine Maintenance Tips: Ensuring Homogenizer Parts Stay in Top Condition

Regular maintenance of homogenizer components is essential for sustaining equipment efficiency and preventing costly operational disruptions. Implementing proactive upkeep strategies reduces performance degradation, minimises unplanned downtime, and extends the service life of critical parts.

• Regular Inspections: Frequent assessments identify early signs of wear, preventing sudden failures. Scheduled checks allow early intervention, reducing the risk of major breakdowns.

• Lubrication Checks: Ensuring proper lubrication minimises friction, reducing component strain. Lubricated parts experience less wear, prolonging their functionality and efficiency.

• Seal and Gasket Replacement: Timely replacement prevents leaks and maintains processing efficiency. Deteriorated seals compromise machine performance and can lead to contamination risks.

• Pressure Calibration: Accurate pressure settings protect parts from excessive wear. Adjusting pressure levels within recommended parameters prevents unnecessary stress on components.

• Clean-In-Place (CIP) System Maintenance: Proper system function ensures contamination-free operation. Regular CIP upkeep prevents buildup and safeguards product purity.

• Valve and Plunger Examination: Monitoring wear levels maintains homogenization efficiency. Worn-out components reduce processing accuracy and affect output consistency.

• Replacement Schedule Compliance: Following manufacturer recommendations preserves machine integrity. Sticking to a structured replacement plan minimises sudden failures and downtime.

• Temperature Monitoring: Managing operating conditions prevents premature component failure. Excessive heat exposure degrades material properties, leading to reduced part longevity.

Reliable Spare Parts Solutions for Pharma Equipment

Amon Engineering supports pharmaceutical manufacturers with precisely engineered homogenizer spare and wear replacement parts. High-quality components ensure machines operate at peak efficiency, sustaining product consistency and minimising downtime.

Enquire with Amon Engineering to secure durable and custom-engineered homogenizer parts tailored to industry specifications.

Read this blog to learn more about our excellent service: Homogenizer Spare and Wear Replacement Parts Manufacturer in Victoria

Explore this content for more information: Homogenizer wear parts and maintenance optimization tips

Optimized by www.NetwizardSEO.com.au