Advanced Ceramics Grinding Services in Melbourne: Advantages Over Other Machining Methods

17 January 2024

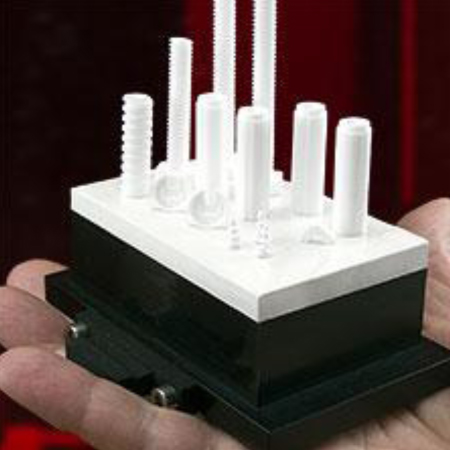

Advanced Ceramic Components

Learn the benefits of advanced ceramics grinding over other machining methods. Offered by Amon Engineering, ensure precision and quality. Call +61 03 9484 1057.

Advanced ceramics are materials highly regarded for their exceptional properties like extreme hardness, wear resistance, and electrical insulation. These unique characteristics make them an ideal choice for a wide range of applications, including electronics, aerospace, and medical devices. But when it comes to shaping and finishing advanced ceramics to exacting specifications, advanced ceramics grinding services offer distinct advantages over other machining methods.

Properties of Advanced Ceramics

At Amon Engineering, we understand the importance of processing advanced ceramics properly. These materials, after all, can be challenging to process due to their extreme hardness and brittleness.

Now, aside from these properties, advanced ceramics or engineered ceramics are known for their exceptional performance in demanding environments. One of the reasons behind this quality is their composition. They are typically composed of non-metallic, inorganic compounds like alumina or aluminium oxide, zirconia or zirconium dioxide, and silicon carbide.

Grinding over Traditional Methods

Advanced ceramics may be processed through turning and milling. However, they can often lead to chipping, microcracks, and other defects that compromise their integrity. Advanced ceramics grinding, fortunately, offers advantages that traditional machining methods cannot provide.

• Precision Tolerances: Advanced ceramics grinding can achieve exceptionally tight tolerances, ensuring components meet precise specifications. This level of precision is crucial in industries where even minor deviations can have significant consequences.

• Boosted Surface Finish: Grinding produces a superior surface finish compared to other machining methods. This quality is essential for applications where smooth surfaces of advanced ceramic materials are critical for functionality or aesthetics.

• Ensured Versatility: Grinding allows for the creation of complex, intricate shapes and profiles with high repeatability, making it possible to generate custom parts and components.

• Minimal Heat Generation: Unlike traditional machining, grinding generates minimal heat during the process, reducing the risk of thermal damage to the ceramic material.

• Improved Edge Quality: Grinding provides sharp, well-defined edges, which can be essential for applications like cutting tools and blades.

• Reduced Waste: The precision of grinding minimises material waste, making it a more environmentally friendly and cost-effective option.

All these advantages of advanced ceramics grinding make it useful in a wide range of applications. The aerospace industry, for instance, can maximise this process to create critical components in aircraft engines and avionics. Precision ceramic components for circuit boards and semiconductor manufacturing can also be produced through grinding. Advanced ceramics grinding can likewise be used to create implants, surgical tools, and diagnostic equipment for the medical industry. Ultimately, this process can produce high-performance cutting tools for machining challenging materials as well as abrasion-resistant ceramic parts for pumps, valves, and machines.

When choosing advanced ceramics grinding services in Melbourne, you should only partner with an experienced and reputable provider. We, at Amon Engineering, are a company with a good track record of working with advanced ceramics and a commitment to quality control. We likewise maximise state-of-the-art grinding equipment to ensure the success of advanced ceramics grinding services. Our capabilities allow us to cater to industries where precision, durability, and performance are paramount.

Optimized by www.NetwizardSEO.com.au