CNC Machining by Amon Engineering: Benefits in Engineered Plastic Production

01 December 2023

Discover the benefits of CNC machining in engineering plastic production. Carried out by Amon Engineering, know how it enhances precision and efficiency.

Engineered plastics, alongside other materials, have become an integral part of modern manufacturing across various industries. And to harness the full potential of these materials, precision and efficiency in production are key. One of the processes that can be carried out to generate quality engineered plastic parts and components is computer numerical control (CNC) machining.

The Essence of Engineered Plastics

Engineered plastics like polyetheretherketone (PEEK), polytetrafluoroethylene (PTFE), and others are known for their exceptional properties. These properties include high strength, boosted chemical resistance, and low friction, allowing them to be maximised in applications ranging from medical devices and aerospace components to industrial machinery and consumer products.

The qualities of engineered plastics may be useful in various applications. However, they can be difficult to process and manufacture. You see, manufacturing precision components from engineered plastics can be challenging as industries often require tight tolerances, complex geometries, and quality material properties, which can only be handled optimally by CNC machining.

With tight tolerances, engineered plastic parts and components can easily fit into their intended places. These products can also become useful once their shapes and features match the needs of industries. Lastly, boasting the right material properties can help industries achieve their desired results.

Major Advantages and Applications

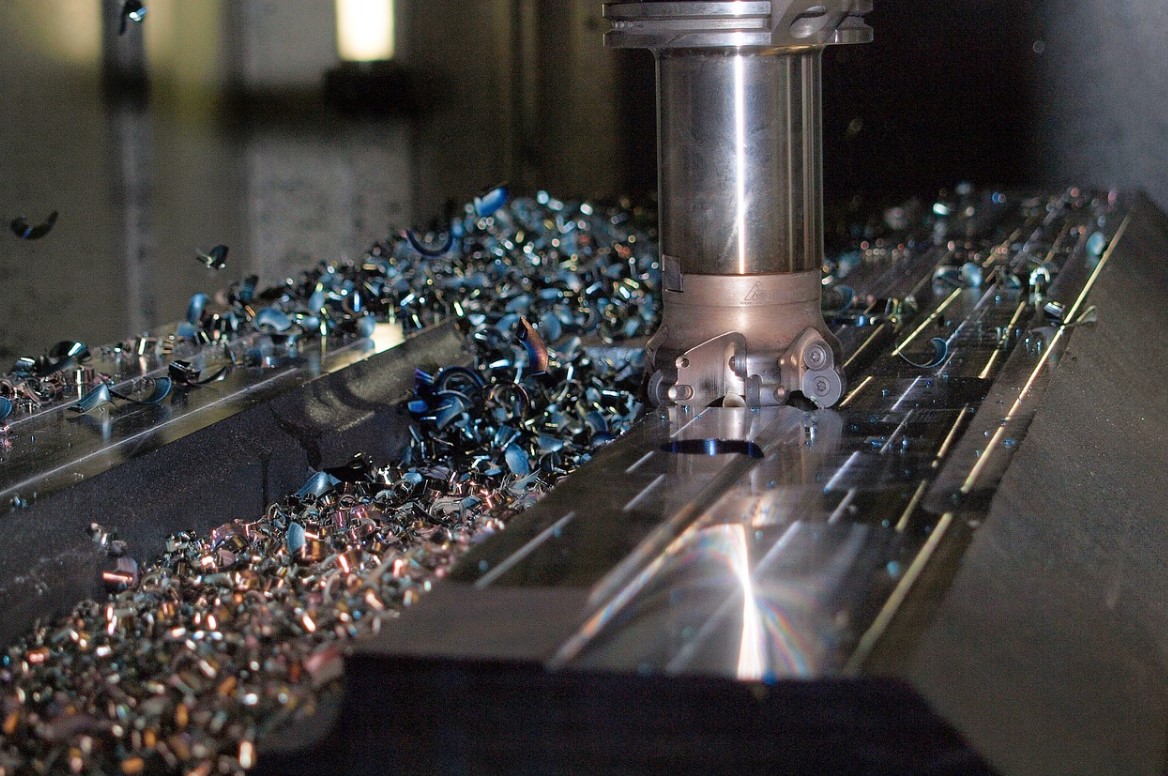

CNC machining can address the challenges of processing engineered plastics due to its extraordinary capabilities. Through CNC machining, industries can expect unmatched precision, allowing for the creation of components with tight tolerances and intricate details. CNC machining can also handle a wide range of engineered plastics. Whether they are rigid or flexible, industries can rely on CNC machining to adapt and process these materials without any issues.

CNC machines likewise excel at creating complex shapes, pockets, holes, and intricate features with ease. Ultimately, automated CNC processes can reduce production time and minimise material waste, optimising efficiency and cost-effectiveness.

When maximised for engineered plastics, CNC machining can easily provide all the previously stated benefits to various industries. The medical industry, for one, can maximise CNC machining in creating precise and sterile components using engineered plastics. The aerospace industry can also take advantage of CNC machining to produce lightweight, durable, and precise aerospace components. The same quality of components can be produced for the automotive industry. Even the engineered plastic parts for consumer electronic products can be generated out of CNC machining.

CNC Machining by Amon Engineering

Effective CNC machining of engineered plastics requires material expertise. Factors like material selection, cutting speeds, and tooling play a crucial role in achieving the desired results. Collaborating with experienced CNC machining providers like us at Amon Engineering ensures the optimisation of these parameters for each specific material and application.

CNC machining has revolutionised engineered plastic production by offering precision, versatility, and efficiency. As industries continue to rely on these advanced materials, CNC machining remains a vital tool in meeting the demands for high-quality components with intricate geometries and tight tolerances. Whether in medical devices, aerospace, automotive, or consumer electronics, this process remains at the forefront of engineered plastic production, driving manufacturing innovation and excellence.

Optimized by www.NetwizardSEO.com.au