Ceramic Bushes for Optimising Bearing Life: Enhance Machinery Efficiency

08 May 2024

Optimise bearing life and enhance machinery efficiency with ceramic bushes. Available at Amon Engineering, discover their advantages and applications.

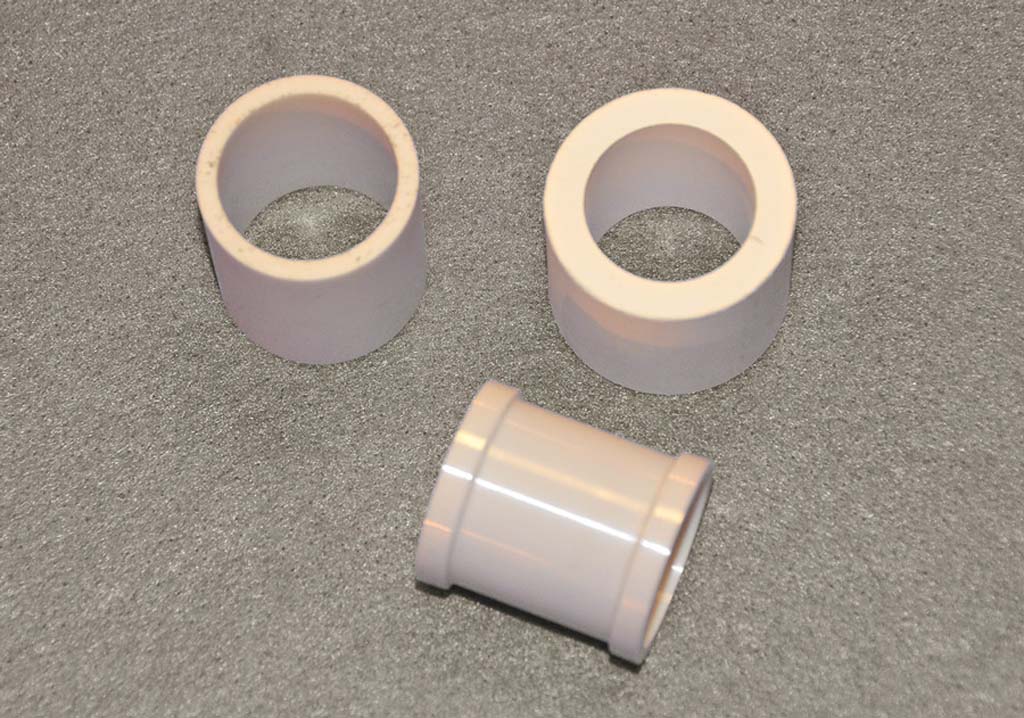

Ceramic bushes are bearings that can enhance the performance and efficiency of machinery across various industries. Like other bearings, they enable smooth rotation and movement of shafts, reducing friction and wear and extending the lifespan of rotating components. Ceramic bushes, however, offer unique advantages that contribute to improved machinery efficiency and reliability.

Ceramic Bushes from Amon Engineering

Amon Engineering fabricates and provides ceramic bushes to industries that require performance enhancement on their machines and equipment. We design and fabricate these precision-engineering components out of advanced ceramic materials like silicon nitride or zirconia.

Producing ceramic bushes involves several precise steps starting with the selection of high-quality ceramic materials, which are finely ground into a powder form. This powder is then mixed with binders and additives, formed into the desired shape, and dried to remove excess moisture. The dried parts undergo sintering at high temperatures to bond the ceramic particles together, resulting in densification and strengthening of the material. After sintering, the ceramic bushes may undergo machining and finishing processes to achieve precise dimensions and surface quality.

Unlike traditional metal bearings, these bushes offer exceptional hardness, corrosion resistance, and thermal stability, making them ideal for demanding applications. Additionally, ceramic bushes are renowned for their low friction, high wear resistance, and resistance to harsh operating conditions, making them a preferred choice for critical machinery components.

Advantages of Utilising Ceramic Bushes

Numerous advantages can be expected when you utilise ceramic bushes. They include the following.

• Extended Bearing Life: Ceramic bushes exhibit superior wear resistance compared to traditional metal bearings, resulting in extended bearing life and reduced maintenance requirements. Their exceptional hardness and low friction properties minimise wear and frictional heat generation, leading to longer service intervals and increased uptime for machinery.

• Reduced Friction and Heat Generation: Another advantage of ceramic bushes is their ability to operate at significantly lower friction levels than metal bearings. This reduces energy consumption and heat generation, resulting in improved efficiency and performance of rotating machinery. Lower friction also translates to smoother operation, reducing noise and vibration levels in equipment.

• Corrosion Resistance: Ceramic bushes are inherently resistant to corrosion, moisture, and chemical exposure, which makes them suitable for use in harsh environments and corrosive applications. Their corrosion resistance ensures reliable performance and longevity, even in aggressive operating conditions where metal bearings may degrade or fail prematurely.

• Thermal Stability: Ceramic bushes exhibit excellent thermal stability, which allows them to maintain dimensional integrity and performance across a wide temperature range. This thermal stability makes ceramic bushes suitable for high-speed and high-temperature applications, where metal bearings may deform or lose their lubricating properties.

Notable Applications of Ceramic Bushes

Ceramic bushes find widespread applications across various industries.

The automotive sector, for one, uses ceramic bushes for engine components, transmission systems, and steering mechanisms. These bearings can also be used by aerospace in aircraft engines, landing gear systems, and flight control mechanisms. Machine tools, conveyor systems, and processing equipment can likewise be integrated with ceramic bushes.

Ceramic bushes from Amon Engineering offer significant advantages in maximising bearing life and enhancing machinery efficiency. Incorporating ceramic bushes into critical machinery components can help organisations and businesses improve uptime, reduce maintenance costs, and achieve greater productivity and efficiency in their operations.

Optimized by www.NetwizardSEO.com.au